A Problem With The Welding Inverter Repaired. Model Handy Stick 180

My brother brought his welding machine for repair. He explained the problem; as he was powering up the welder the earth leakage keeps tripping.

He had this machine for almost 15 years and although it looks beat up and old it is still doing what is supposed to do.

I powered up the machine and as I pushed the power button, the earth leakage in my shop was tripped as my brother explained earlier. I did not do any welding with it, just plug in the power cord and push the power button on.

From experience, when something like this happens I usually go to the IGBT and the Diode rectifiers and check them out. To do that, I had to take a lot of screws to get to them.

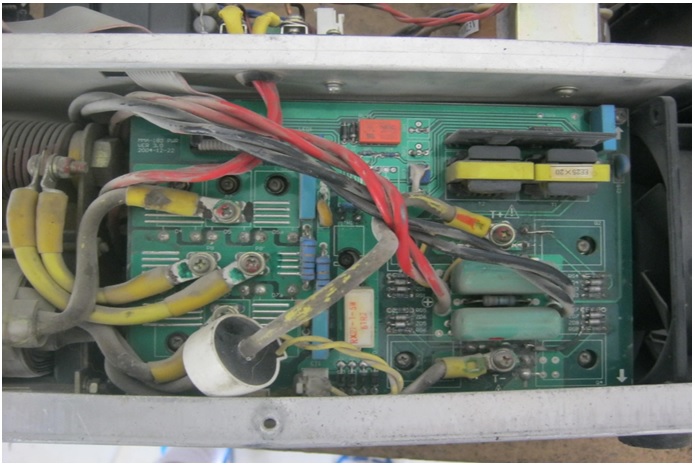

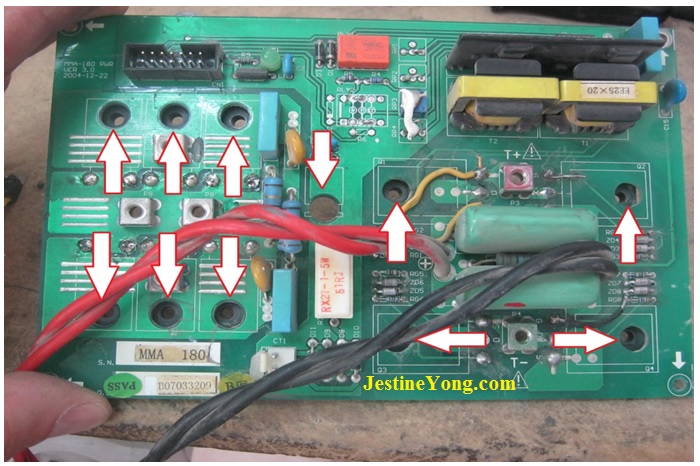

I had to take the screws that are holding the yellow cables off and then the screws that holding the IGBT and the diode rectifiers.

This board is sitting on a big heat sink plate which is facing the cooling fan to keep the IGBT and the diode rectifiers cool when operating the welding machine.

You could see the gap left behind as I took the main logic board out for checkups.

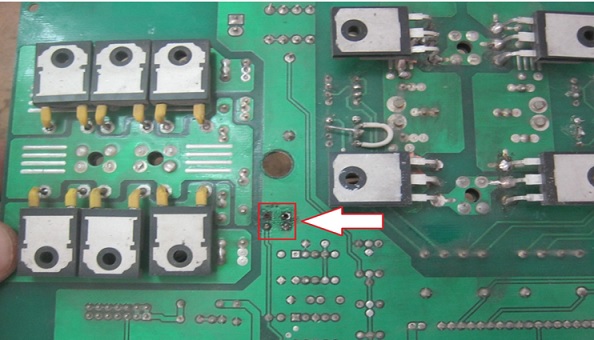

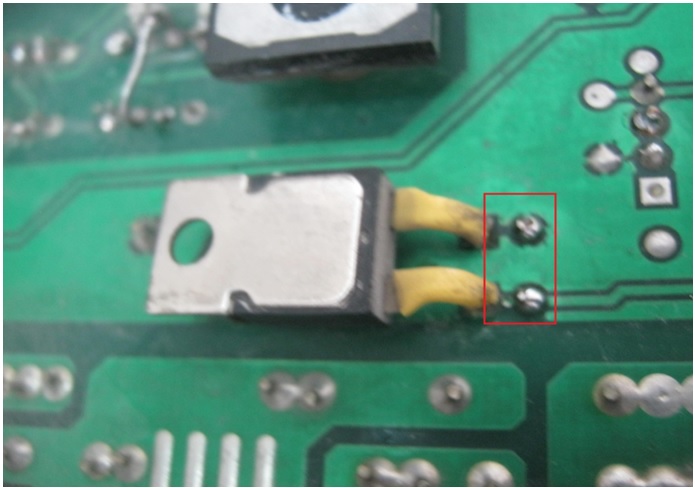

All the IGBT and the diode rectifiers checked fine but I could see one part that has loose pins and was soldered to the main board.

It turned out to be a thermal fuse that has loose pins. I re soldered its pins back to board. I do not think that was part of the problem that I am trying to solve.

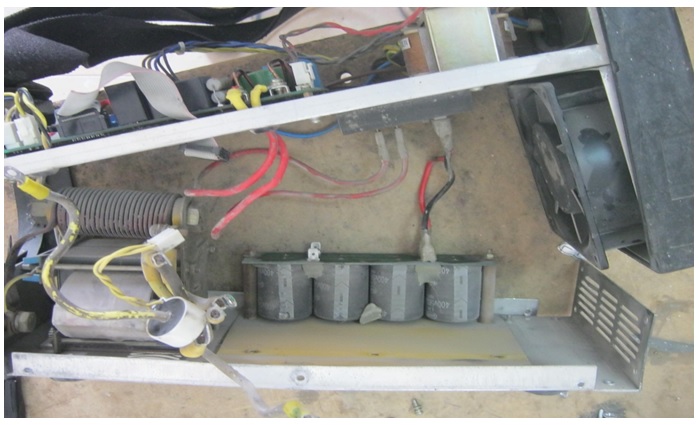

My second step was to isolate the problem. My second suspicious parts where the bridge rectifier and the main capacitors.

I disconnected the main bridge rectifier from the main capacitors and powered up the machine. The fan came on and the green light came on steady and this time the machine did not trip the earth leakage key.

I connected the main capacitors back to the bridge rectifier negative and positive terminals but this time I disconnected the cable that goes to the main board and guess what? As I powered up the machine, the earth leakage in my shop was tripped the moment I hit the power button.

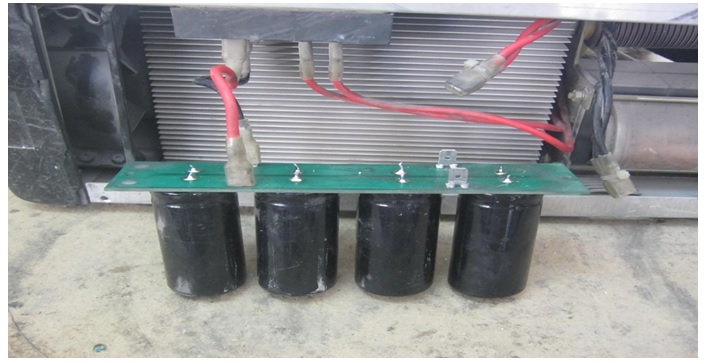

There are four capacitors in this device. They are 560 UF/400 volts. If you look where the arrow is, you could see a black spot started to form on the negative pin of the capacitors.

This is one of the pads that were covering the capacitor terminals and it showed dark spots on the negative pin of the capacitors. I found the same mark on all the capacitors.

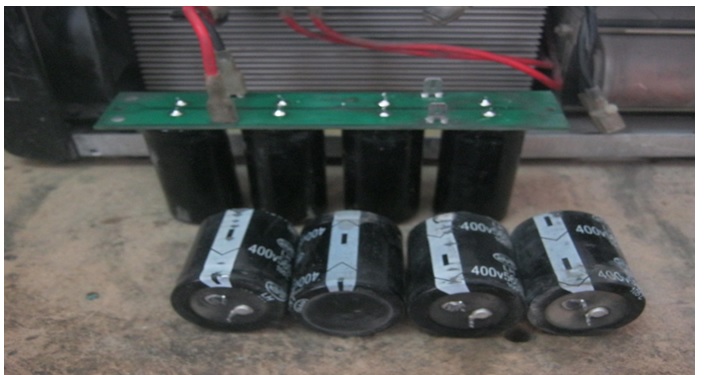

I have the same value capacitor but the main problem; they are little bit longer. I decided to give it a try and see.

Once I powered up the welder, the green light came on and the earth leakage did not trip which an indication that the issue was resolved.

Different in size but I managed to fit inside the machine.

Mission Accomplished.

This article was prepared for you by Waleed Rishmawi, one of our ‘Master Authors’ and currently working in the Bethlehem area of Palestine repairing electrical and electronic equipment.

P.S- Do you know of any your friends who would benefit from this content that you are reading now? If so, forward this website to your friends or you can invite your friends to subscribe to my newsletter for free in this Link.

Note: You can check his previous repair articles in the link below:

https://www.electronicsrepairfaq.com/a-dead-digital-soldering-iron-bought-back-to-life

An expert like you, is someone who resolves all the issues irrespective of its nature! Great work there!

Parasuraman: thanks man. have a blessed day

This repair sure thing just had to come from the master of welder repair himself!

On your previous repair you tipped us to buy enough IGBT transistors in case a welder needs to be repaired which I did. But I guess also having four 560uF 400V spare e-caps is in your case no coïncidence either after having fixed so many welders before.

Albert: every machine almost works the same but most of the time it has different parts and in order for me to do the repair, I need to keep up with all these parts. every time I see different part number I order and keep in my workshop and that way, you are doing the repair the way it should be. this time the capacitors are fault and yes, I have plenty of them in my shop because I repair them..have a blessed day

well done! welder specialist……..

Yogesh: thanks man. have a blessed day

Very straight forward and easy to learn steps for beginners like me. Thank you Sir.

xavier: I am glad you like the article. we are started like beginners then with experience we can repair what needed to be repaired. keep up the good work my friend. never give up. have a blessed day

Your article is really good and practical

Hi Waleed,

Great article, and great pictures. Jestine doesn’t do welders,

so do you have a welder repair book out or could you recommend

one or more books that simplify welder repair.

Thanks sincerely,

Barry