A UPS board With Some Damaged Areas Repaired and Maintained

A technician in a medical company brought this board for repair. He brought only the board and nothing else with it. It was really damaged. As I talked to the technician, I informed him since I do not have the complete device to work with; I can only fix the damaged parts and that does not mean it will work. It might work and it might not either way, I getting paid for the time spent or parts replaced on that board. As we both agreed to that, I proceeded with fixing and maintaining the damaged area already seen in on this board. Take a look

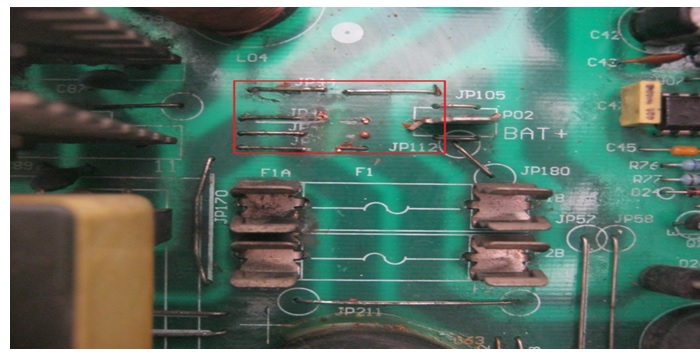

Jumpers are already cut close to the battery terminals and fuses are missing and I do not know even the ratings on these fuses.

Just over that damage are I could see a bulged capacitors and it was clear to me that over load took place and something went dead.

To the right of that bulged capacitor there are six capacitors lined up together and beneath them found that corrosion resulted from the paste they put around components to keep them fastened during shipment. That white paste changed into conductive material which I am assuming the main reason behind the damaged found on this board.

First step was to clean all this corrosion, reconnect the jumpers, replace the bulged capacitors and hope for the best.

As agreed with the customer, this was all done in the shop, then his responsibility to try it out and in case it did not work, he has to bring the rest of the device and the batteries and then work on them the way it should be.

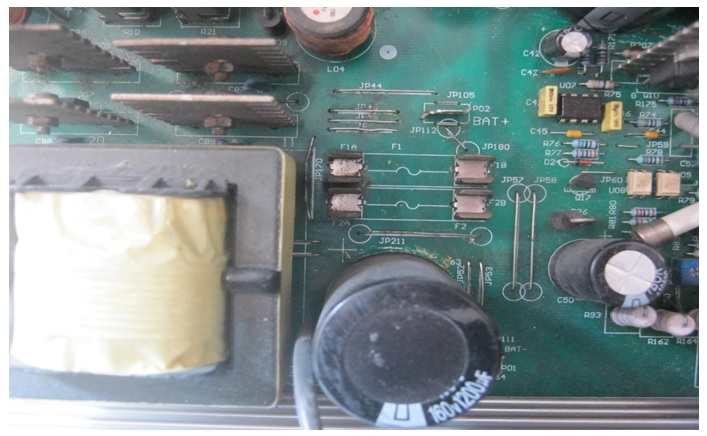

New jumpers were installed

New capacitor was installed. It was 1000uf/16 volts. I did all the cleaning and called the customer. Recently found out that the rating of these fuses were 20 amps each.

To my surprise, he called the next day and said it was working fine. To be honest with you all, I was not expecting that thing to work again but it did. If the customer was happy, then I am happy and to that I could say

Mission accomplished.

This article was prepared for you by Waleed Rishmawi, one of our ‘Master Authors’ and currently working in the Bethlehem area of Palestine repairing electrical and electronic equipment.

P.S- Do you know of any your friends who would benefit from this content that you are reading now? If so, forward this website to your friends or you can invite your friends to subscribe to my newsletter for free in this Link.

Note: You can check his previous repair articles in the link below:

https://www.electronicsrepairfaq.com/medical-device-power-supply-repaired-model-up30431

Those UPS currents are like those high currents in the welding machines extreme and although they are mostly at low DC voltages, they are real fire hazards and become dangerous when handled by unqualified engineers! But the fact that you are a well trained and practical master who uses the right 20A fuses, prevents anything bad from happening. Making sure no copper tracks or components will burn through because of unsafe replacements! Assuring the long life of the UPS and making another customer happy!

Albert: thanks for your input my friend. have a blessed day

Well done Waleed

Mark: thanks man. have a blessed day

Well done, though a wild shot! But for a careful and practiced shooter, ‘target’ is not a problem! So is it, when a device reaches your hands!

Parasuraman. thanks man. I appreciated your sweet words of encouragement. have a blessed day