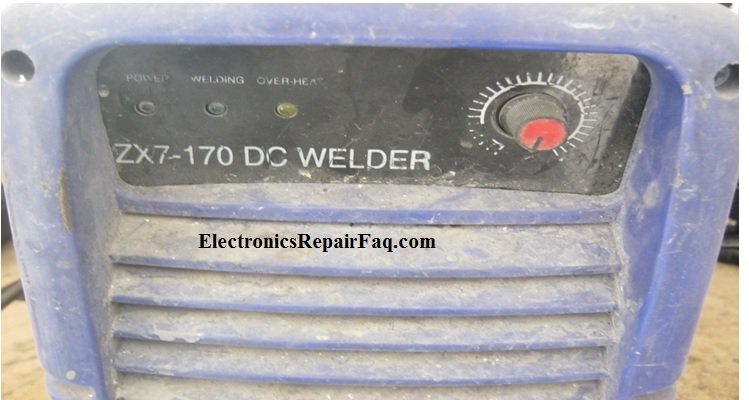

Electronic Welding Machine Repair- Toper ZX7-170 DC

An Italian made welding machine was brought to my shop for repair and the problem was a dead machine. A no power issue is very easy to fix in welding machines. We always expect the worse but it comes to the simplest fix ever.

These kind of welding machines are usually taken for granted. People who operate such machines do not bother to do any kind of maintenance on it therefore damaging it on the long run.

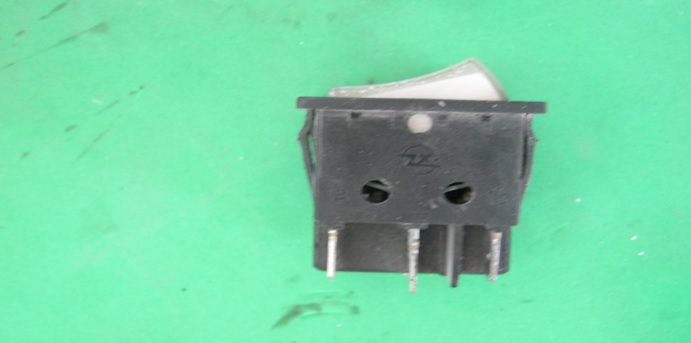

I powered up the machine and there was no indication of a working machine. I pushed the power switch on and nothing. I could not hear the click in the power button. Further testing I found that the main power swtich was dirty but with cleaning, it did not solve the problem so I had to change the power switch. The moment I did that the machine came on and the fan started spinning.

I can see that the machine was on but when I tried to weld with it, it was dead. So I am half way with this repair.

That is the bad power switch that was replaced.

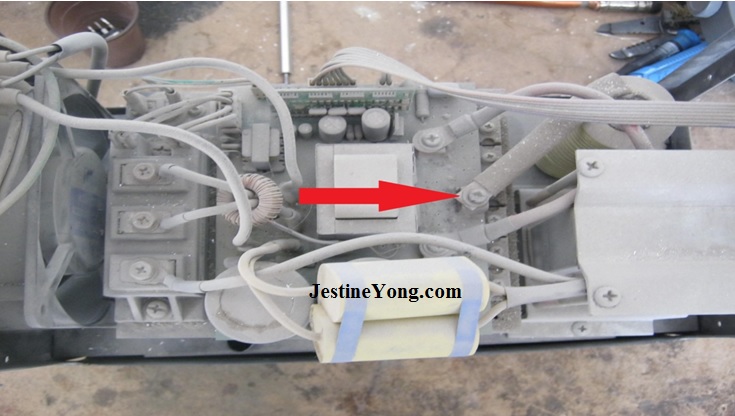

This is the inside of the welding machine and as you can see it was dirty. I got my dust blower out and cleaned the machine. After the cleaning, something was revealed and immdiately the problem was found. If you check the red arrow in the photo, it is pointing the positive terminal on that machine. It was lose.

I have to solder it back to the board. it was a long process but finally it was done.

As you can see the power was on but that did not help till I soldered the postive side to the board.

The way to test the welding machine if it is working or not is try to weld with it but there is also another way of finding out. It is by measuring the the output on the from of the machine. There are red and black terminal. Set your meter on DC scale and test the output. The voltage reading is different in every machine. This one was only 11 volts.

Mission Accomplished.

This article was prepared for you by Waleed Rishmawi, one of our ‘Master Authors’ and currently working in the Bethlehem area of Palestine repairing electrical and electronic equipment.

P.S- Do you know of any your friends who would benefit from this content that you are reading now? If so, forward this website to your friends or you can invite your friends to subscribe to my newsletter for free in this Link.

Note: You can check his previous repair articles in the link below:

https://www.electronicsrepairfaq.com/how-to-repair-a-dead-air-condition-circuit-board

Well done!

Hi Jestine

This welding machine repair was of great interest.Just shows what constant maintenance could achieve.Thank you

Love it! Wish mine was that simple!!

Good Job! Waleed,

Thanks for sharing.

Speaking of dirty, this welder was really hardly recognizable under all that dust! Thanks for the article Waleed and the output measuring suggestion. I believe that my Sunkko 709a 2 in 1 spot welder only delivers a max of about 5V DC. And we also should be able to measure the current of a good working device. Here an interesting link to someone who had opened the 709a spot welder machine to have a look inside:

https://www.eevblog.com/forum/reviews/sunkko-709a-spot-welder-teardown/

Oops that probably must be 5V AC!

I have come across different machines with different problemstyles, I have successfully fixed most of them, now I have got about 4threephase machines,and it’s a challenge since I don’t have the 3phase electricity installed at my shop.so when I fix the fault,I have to try it somewhere else!is there away somebody can run the machine on single phase even if it’s athreephase machine? Lastly about the output voltage,Watson the maximum

Great repair with simple diagnostics.I like this repair. Thumbs up!!!

Good observation gives good result. Well done.informative article.