GW40V60DF IGBT Shorted

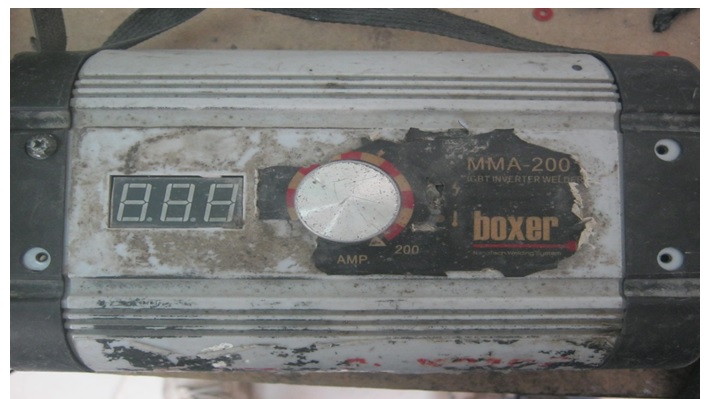

One of my regular customers brought this welding machine for repair. I have not seen this kind before but like I said before, they are all the same and do the same job.

It is a dead welding machine and as always I check, the cable, power plug, power switch and of course capacitors.

There are no fuses to check on these machines so when they are dead they either have shorted parts inside or the power is not getting into the machine. Let us find out.

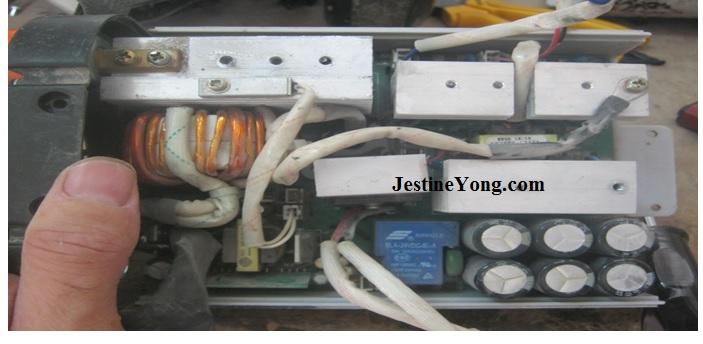

There was power reaching the main capacitors which is a good indication that it was getting the right voltages but for some reason it was not working. Usually I head after that to the main either Mosfets or IGBT. In this case they were IGBT’s located nearby in this tiny crowded welding machine.

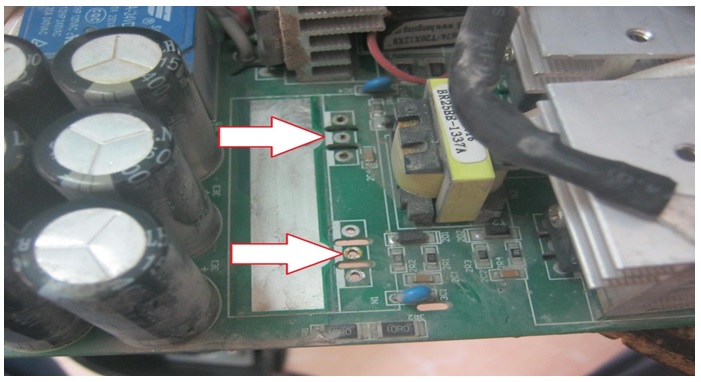

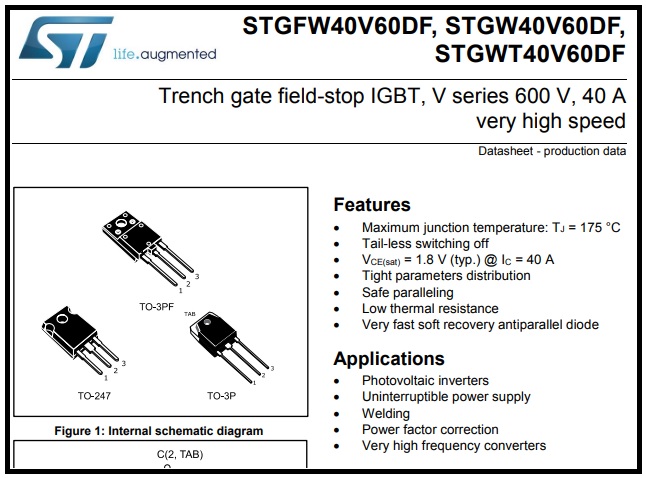

The IGBT part number that I found shorted in this area GW40V60DF. There were two of them shorted and need to be replaced.

You may click on the photo above to access the datasheet.

Getting to these IGBT was not easy due to the fact that it was a tiny machine but finally when I took these off board and tested them out they were all shorted on all their pins.

It is a common thing when these parts are shorted the machine will not start or in other words, the machine safety is protecting itself from being damaged further. So it is a common sense to check these parts if you face such issues of welding machine completely dead. In some other machines, they were be no voltage reading at the main capacitors which might bring you to believe it has issues with getting power in the machine.

Once these IGBT’s were replaced with the same exact part number I was able to power the machine but after I checked around to make sure there are no other shorted parts around.

By the way, after removing these shorted parts off board, and you power up the machine without the new replacement, if all is well, the machine will come on but it will be too weak to weld. That is how I check everything is fine before I install the new parts.

Anyway after replacing the parts, and powering on the machine, it was alive again and my brother, the welder was able to give it a try and see how it was and as always it passed with high stars.

Mission Accomplished.

This article was prepared for you by Waleed Rishmawi, one of our ‘Master Authors’ and currently working in the Bethlehem area of Palestine repairing electrical and electronic equipment.

P.S- Do you know of any your friends who would benefit from this content that you are reading now? If so, forward this website to your friends or you can invite your friends to subscribe to my newsletter for free in this Link.

Note: You can check his previous repair articles in the link below:

https://www.electronicsrepairfaq.com/fog-machine-with-broken-socket-and-loose-wires-repaired

There are no fuses to check on these machines sounds like a Microwave-combi oven (A Bosch HFT420 Gourmet 2200, 3.1kW 230VAC) I recently opened where I didn’t find any fuse in either. It only had a special electromagnet safety switch that connected through both upper HV capacitor contacts of the 3 contacts on the very big special capacitor when the Microwave was activated. The oven still worked fine, the HVR-1X diode was fine and no parts were found defect, but it must have had a bad contact in that switch why it sometimes didn’t switch on.

Your conclusion that the Welder machine safety is protecting itself from being damaged further without any real fuse inside was something I imagined recently myself also. Great article and thanks for another handy datasheet!

Albert: when dealing with 200 amps welding machine what kind of fuse that can handle such load. on the top board usually there is a fuse but the lower board where the IBTS’s and mosfets are, there is not fuse except a thermal fuse but not all machines have such protections.

Good Job there! You must by now have crossed hundreds of welding machines!

Parasuraman: thanks man. I have crossed a lot of these welding machines but still there a lot of machine in the market that I am still learning from and dealing with finding answers to their issues. have a blessed day

Thank you for the article. I actually went and researched what an IGBT was and its applications. I would have been too scared to turn this or any other machine with a missing component. Quite often nothing happens but every once in a while you get a loud POP!

Tayo: you are most welcome. I am not talking about totally missing parts. I take the shorted ones out and make sure to leave at least one on that line and when powering on the machine there is no load on it. this is just a procedures that everything is fine and not worrying about popping parts inside the machine. have a blessed day

Thank

Hi sir very good article. But i have a question, i’m also electronic repair living at gabon and in my area we’re facing a problem: it’s to hard to find electronics parts here and when we can find them some are false specially these igbt for welling machine and plasma tvs… can i find good igbt parts in your country?

Thanks in advance