How To Repair Intermittent Problem In Inverter Welder

This welding machine was brought to me about one month ago. It had intermittent problem with it when it comes to welding. The first time was brought to my shop, it had a lot of cold soldering joints and I re soldered every joint in this machine. To my surprise, this same machine came back to me after one month again with the same exact problem.

I think it is a Turkish made machine. This guy sells used and brand new machines.

In my country, our main product either made in china or turkey and if you afford to pay more money, you would get better products that will last longer and give you better quality results.

Since the main problem was sometimes it welds fine and sometime while the machine is on it does not weld, the only way to find out the problem is by doing a lot of welding and hopefully I will find what is wrong with it.

The first two minutes it was welding fine but I noticed after five minutes as I heard a noise coming out of the machine and I could not weld no more. If you look at the photo, the red light came on. It is an overheating issue if this LED light comes on while welding. My chain of thoughts was focused on the noise that came out of the machine. It sounded like a discharge noise. I decided to take it apart.

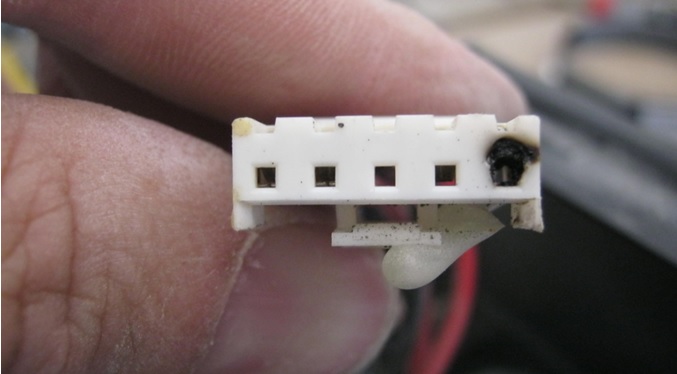

As I was taking it apart, look what found. In this situation, the burnt smell led me to this finding. I considered myself lucky to find it that soon before dismantling this machine.

This is the other side of the plug that feeds the two transformers bellow the Mosfet heat sink.

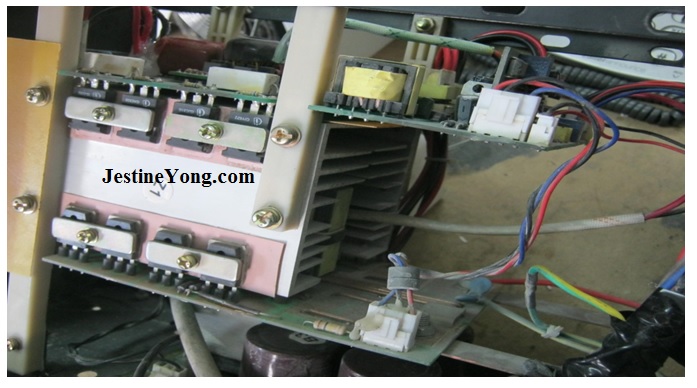

It is a pain to get to these transformers out as you can see in the photo.

I got rid of the plastic plug because it was already burning and then cleaned the contacts, cut the main wires off soldering them to the cleaned pins and add silicon to them.

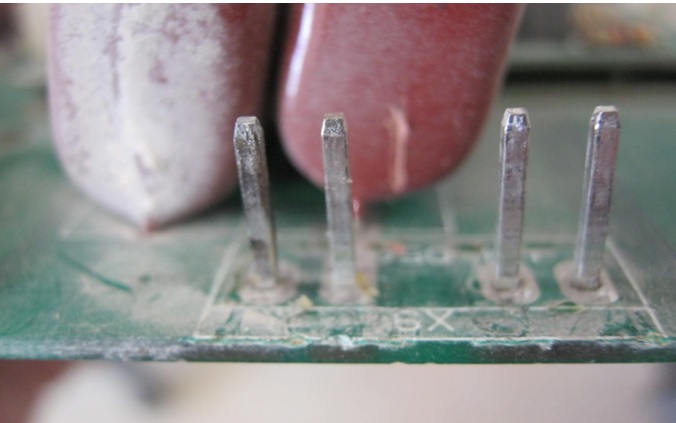

These are the pins on the main board.

Silicon added to the pins soldered to the main board was a precaution step to avoid pins touching and causing damage to the machine.

I took the machine to my brother who is a welder, test it for almost the whole day and it did not cause any welding issues. I was happy with the results and I am sure the customer was too.

Mission Accomplished.

This article was prepared for you by Waleed Rishmawi, one of our ‘Master Authors’ and currently working in the Bethlehem area of Palestine repairing electrical and electronic equipment.

P.S- Do you know of any your friends who would benefit from this content that you are reading now? If so, forward this website to your friends or you can invite your friends to subscribe to my newsletter for free in this Link.

Note: You can check his previous repair articles in the link below:

https://www.electronicsrepairfaq.com/heres-a-quick-way-to-repair-cash-register

Good job Waleed.

Thank you

Good job!

Thank you

You are the King of fixing Welders!

Not yet but working hard to reach that level. Thanks for the encouragement.

Hi Walid

In fact I repair a lot of this kind of welders made by China such as Jasic is number 1 of quality, then there is a lot of copies with différents names. But I never encountered this problem with loose pin connector! The common problem of this brand is yellow led on, no welding it means no voltage at the output then HF ignition. I consider this machine is easy to fix in comparison of other européen and USA brands like esab Lincoln saf-fro, cea Italy, fronius etc… so I conclude, as you said this field requires a common sense and a lot of efforts and studies, good continuation

Very good indeed, thanks for sharing.

Hi!

Yea, some time very simple repairing make very complex think working and vice versa.

Most important for me when I repair is, to exam every part what I take of.

To figure out smells, burnt points, broken point etc. before I run to

some complex stage of repairing.

As you did.

Nice job done, but I have a question:

do you figured out why this pin was overheated?

Two thinks come to my mine:

1. bad soldering joint on the pin

2. overloading the pin

My best regards…