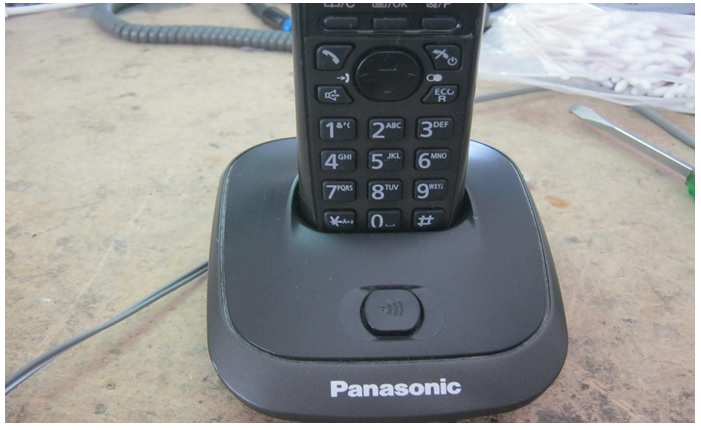

Panasonic Cordless Phone Microphone Repair

A Taxi driver and also a friend of mine called me from a land line and when I answered the phone, the sound coming from his phone was faint and hard to understand what he was saying.

As he brought the phone to me shop I knew exactly what to do because I was familiar with the problem and went right away to solving this issue.

The phone was charging fine and I could see that displayed on the phone screen. From experience, I headed directly to the source of the problem, which in this case the microphone circuit.

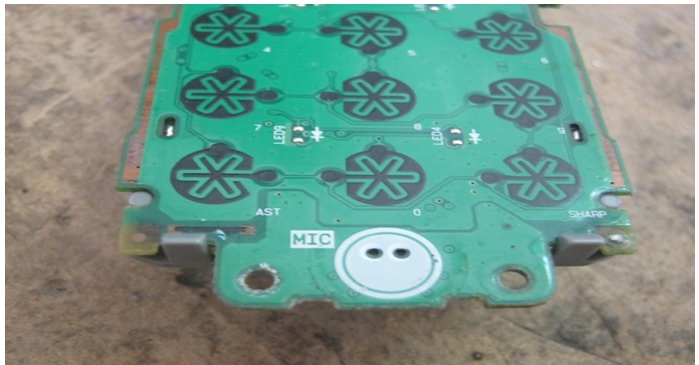

Two screws were off and I was able to see inside the phone. It looked nice and clean but that does not mean it was not faulty.

Usually I find cold joints there but in this case, re soldering the joints did not help. It was time to take the microphone off and replace it with another one

Taking the microphone off the board it is very easy but putting the replacement one back on is easy too but it requires some attention. By attention I mean, the microphone is very sensitive and it might be damaged if exposed to a lot of heat.

In other words, when putting the replacement microphone, use heat as low as possible and try not to keep the soldering iron touching the pins of the microphone for too long.

There are two sizes to these microphones but in this case it was the tiny one and they are hard to find. I usually buy phones that are faulty beyond repair or might me too expensive to repair; I take these microphones off board and keep them in my shop.

Once I installed the replacement microphone back on board and put everything together, I called the customer cell phone from his land line phone. When he answered; I asked him about if he can hear me well and he responded with a happy voice that it was loud and clean.

That was the testimony of the customer himself and that was music to my ear.

Mission Accomplished.

This article was prepared for you by Waleed Rishmawi, one of our ‘Master Authors’ and currently working in the Bethlehem area of Palestine repairing electrical and electronic equipment.

P.S- Do you know of any your friends who would benefit from this content that you are reading now? If so, forward this website to your friends or you can invite your friends to subscribe to my newsletter for free in this Link.

Note: You can check his previous repair articles in the link below:

https://www.electronicsrepairfaq.com/a-wireless-microphone-dismantled-and-fixed-model-pdwm-2600

Thanks for the advice Not to use too much heat on these small microphones! A few months ago I started to quickly remove all passive and active components from at least of 9 different mainboards for collecting spare part components. I found using my hot-air station a very effective way in doing that very quickly without destroying any component. Using an old solder iron station is a very slow and cumbersome way to remove parts why I stopped desoldering parts the old way. Especially in cases when we have to remove those bulged bad low ESR mostly 6.3V e-caps from computer mainboards, using an hot-air solder station proofs to be an effective and better way to remove them. Also because the through solder holes are so tiny that we often can’t remove the e-caps with our solder iron without damaging the copper tracks in the proces.

Albert: thanks for the input. I will keep that in mind. as technicians we always find a way to make our work go faster. For me, the Hakko soldering iron that has different kind of tips and I can control the temperature is easier than hot air. Mainly my hot air station I mainly use for iphone repair especially the IC with the soldering balls beneath the chip. have a blessed day

Thanks for sharing. That was an easy fix.

Devon: yes very easy repair job but it was necessary. have a blessed day

Thanks Waleed,

Thin Track is the first victim in multi-layer through hole PCB when using soldering iron even using temperature controlled Iron also damage the track.

Yogesh: it was done without any damage. What can I say: I am good. Lol.

thanks for supporting ,Jestine.