Positive and positive terminals on a welding machine replaced

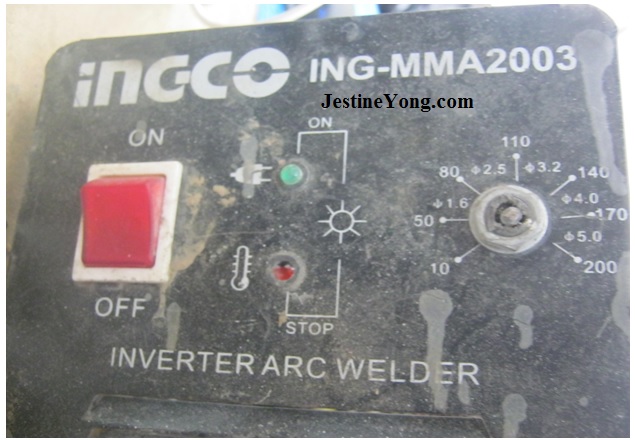

A welding machine was brought to my shop for repair. I have repaired so many of these kinds of welding machines. This time it was a different kind of repair and it was a straight forward repair. Take a look.

It is a beat up machine. All the welding machines that I get from this guy for repair are very abused and not taken care of.

Even after the repair and maintenance of these machines, the next month and even weeks I got them back in a very bad shape. I have called the guy so many times to give him an advice how to treat the machine but it all this effort was wasted in vain.

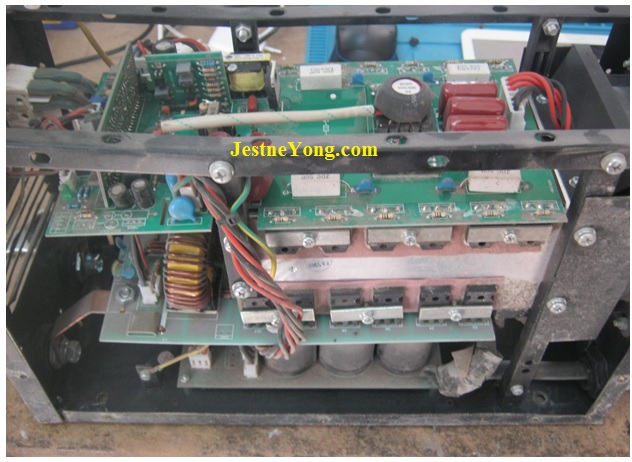

This time, the fault was not in the electronic parts but something else. It was the positive and the negative terminals of the welding machines.

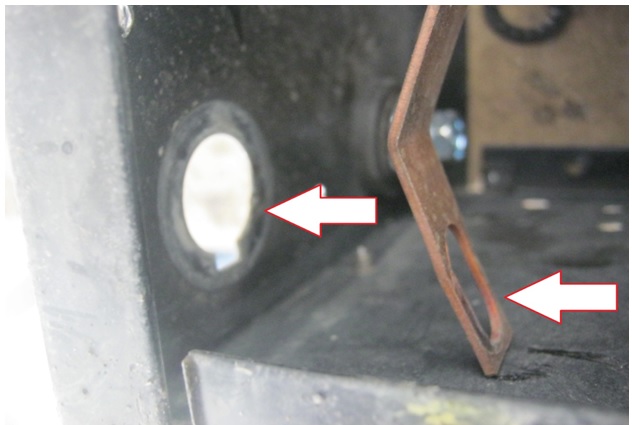

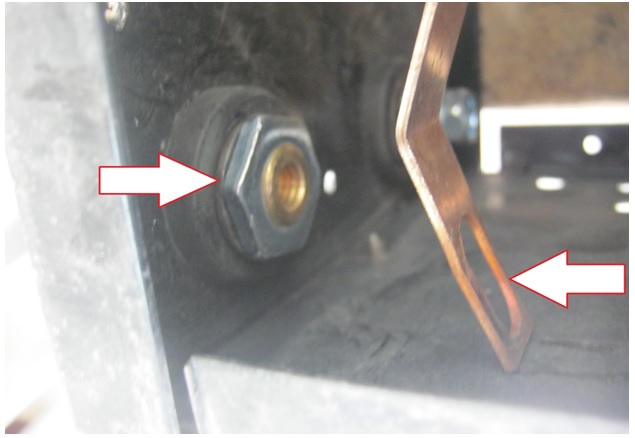

I replaced one of the terminals to show you the difference between the two

This is the replaced part and as you can see, it is pretty bad and it has to be replaced.

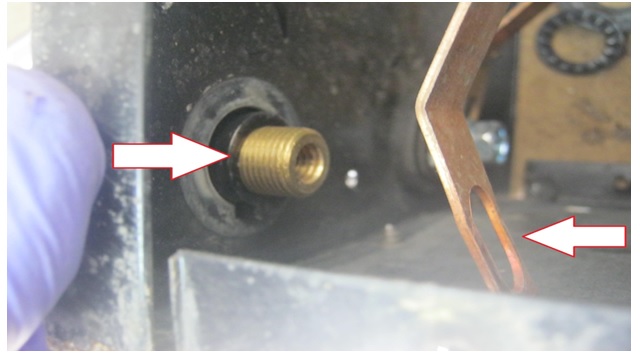

Look how shiny it is.

The process of replacing these terminals is very easy but one thing to remember is to isolate especially the positive side from touching the body of the welding machine.

Take the screw off and the plastic part comes off as you can see.

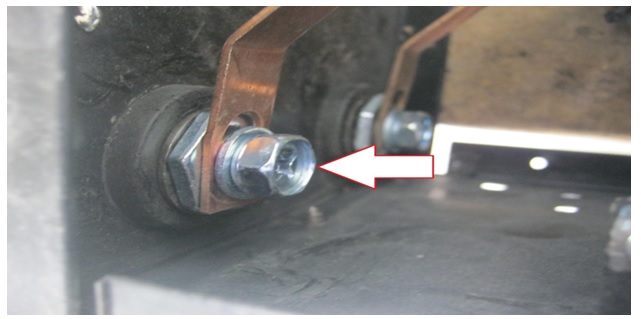

Add the first part to the machine and then add the next one to it.

The other plastic part comes on from inside the machine then you add the nut over the screw of the external part.

Next, put the metal part and tie the screw on it. In this way, it is isolated and ready to go. Just make sure it is tight enough to do the job.

This is the final replacement of both positive and negative terminals. This machine is ready to do the function it suppose to do but I have a feeling I will get this machine in the shop in one month of so. Any way, Mission Accomplished.

This article was prepared for you by Waleed Rishmawi, one of our ‘Master Authors’ and currently working in the Bethlehem area of Palestine repairing electrical and electronic equipment.

P.S- Do you know of any your friends who would benefit from this content that you are reading now? If so, forward this website to your friends or you can invite your friends to subscribe to my newsletter for free in this Link.

Note: You can check his previous repair articles in the link below:

https://www.electronicsrepairfaq.com/a-smoking-welding-machine-repaired-model-ing-mma2003

Micro spying cameras become so small and cheap that one of these days we maybe can mount one secretly into any device to take snapshots showing how exactly the user is abusing his device. But by then the assurance rules may have changed too helping us to charge more for any timeconsuming repair. Lets hope the guy takes better care of his welder this time.

No such luck. This guy is an abuser of all the machines he brings to repair.

Job security?

Thanks Waleed, for sharing your experience. I´d never serviced this type of equipment. So, I am glad to know something more.

Good job, Waleed.

Thanks Robert.

I am glad that you show us the basics again in these types of unsophisticated repairs -Back to to the basics.Thanks-Dan

Thanks dan. Strong foundations of basics is what keep us going.

if you dont try to repair any thing you have never worked on before you will never gain experance ime a great believer in if it was put togather it can be taken appart common sence tells us that, the only time i was beat i wassent thier, and ime second to none?.or so i tell my self god bless one and all.

Good job well done and i also have one challenge with a welding machine and very soon i will post to you problem for your advise.

Thank you Waleed.

With regards Charles from Uganda.