Shorted IGBT On A Welding Machine Replaced

A guy called me urgently about his welding machine. He said that it stopped working because the welding technician by mistakes bumped into it causing to stop working. I always listen to the customer but I usually do my own checking later on.

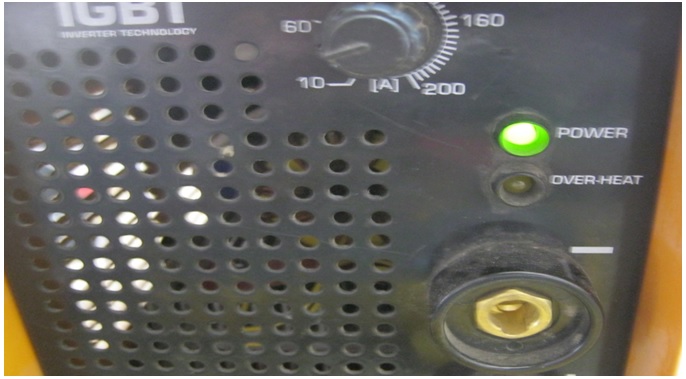

The moment I powered up the machine, I saw this right away which is a common fault in this kind of machines. The overheat LED light comes on due to many reasons.

One of these reasons is the IGBT or Mosfets get shorted causing the logic board of the machine to send a signal that something is wrong and give it the command not to function otherwise, it will do more damage to the machine.

There are no voltage readings on the negative and positive out of this welding machine therefore, no welding is being done. It has to be at least 50 volts coming out depending on the brand name of the machine.

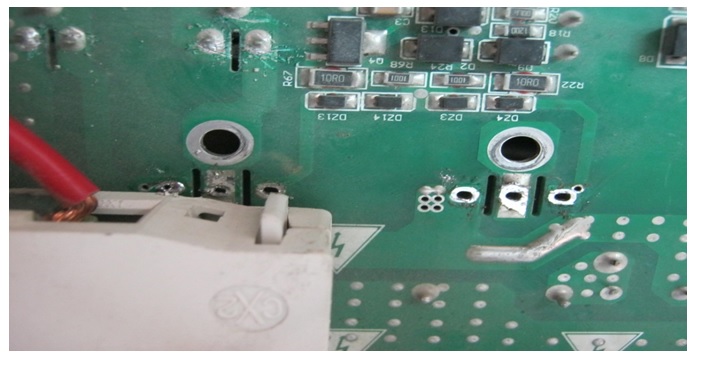

I took a lot of screws off and took the cover off. I went directly to the IGBT on this machine and right away, I found this.

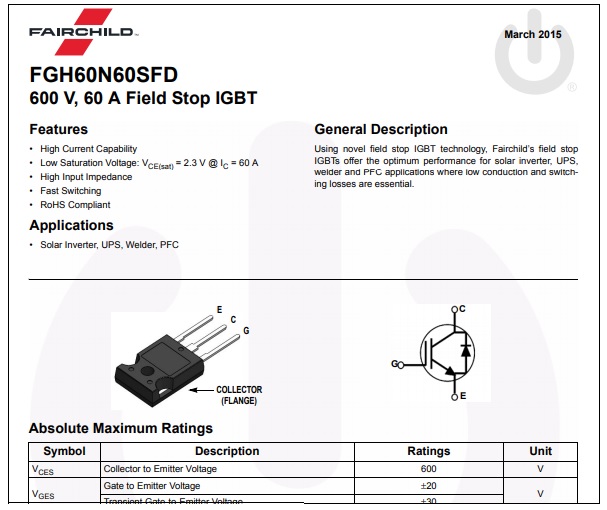

With my multi meter set to diode setting, I found out that these two IGBT where shorted and needed to be replaced.

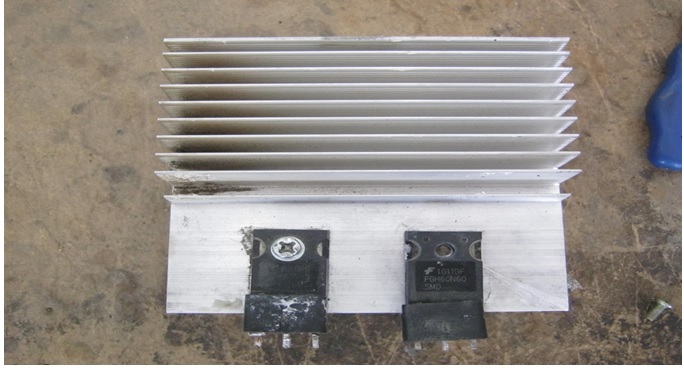

They usually come attached to big heat sync for cooling purposes.

There are other two IGBT on the other side of the welding machine but they all checked fine.

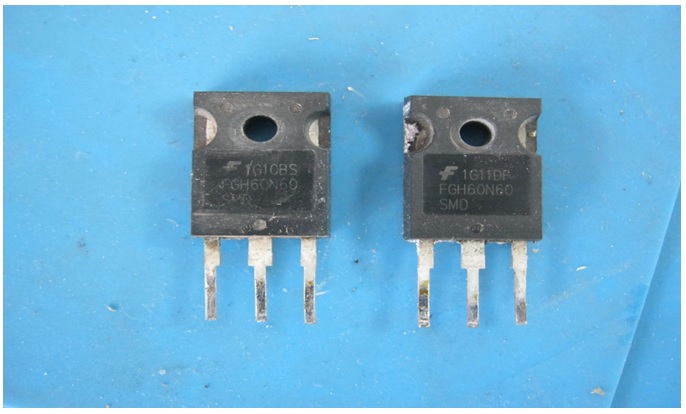

As you can see in the photo, these are FGH60N60. These are very hard to find, I usually order them on line. What you see in the photo is the good parts not the shorted ones. You can click on the photo below to view the pdf file of this component.

I was able to find used parts in a local repair shops that deals with welding machine repair. He was willing to sell them to me but they were not cheap.

How do I know that the machine is fixed? After I de soldered the parts off board, I powered up the machine and heating warning was off. This is a clear sign that all is well and all I need now is to install the good parts back on board and test the machine.

As you can see, the voltages are back to the negative and the positive pins of the machine. You can say now, the machine is alive and kicking. As always, I let my brother test it for me and it was working fine.

Mission accomplished.

This article was prepared for you by Waleed Rishmawi, one of our ‘Master Authors’ and currently working in the Bethlehem area of Palestine repairing electrical and electronic equipment.

P.S- Do you know of any your friends who would benefit from this content that you are reading now? If so, forward this website to your friends or you can invite your friends to subscribe to my newsletter for free in this Link.

Note: You can check his previous repair articles in the link below:

https://www.electronicsrepairfaq.com/laptop-power-supply-repair-model-targus-apa32us

Excellent professional service! Well done!

Parasuraman: thank you. I appreciate it very much

Mr. Welding fixer was at it again! Good job and thanks for the article.

Albert: you are most welcome. I am glad you liked it. I like my new nick name. have a good and blessed day

Great job..enjoy your arcticles.

Josh: thank you. I am glad you are enjoying them. have a blessed day

como comprueba un igbt sin equivocarse solo con un multitester digital

==============================================================

How to check an igbt without being mistaken only with a digital multitester

Ricardo: there are a lot of video on you tube that can help you understand and test IGBT. it is better to check them out there. have a blessed day

Interesting article wow Waleed please keep on posting these valuable articles ,they are so educative.

Di you have a shop along batangas? I cnt repair my welding machine. I dont know hw to repair.