Welding Machine Repaired. Model: Inc-comma 2003

A welding technician came to my shop and explained the main problem with this welding machine. He said, the moment he starts to weld, it worked for a minute or two then it stops.

He did not explain to me the meaning of “it stops”. I have to find out on my own.

Does it mean it stops welding, or the whole machine shuts down? I am not really sure. So I took it to my brother’s welding shop next door and asked him to work on it. He worked on it for almost five minutes and it stops. That means, it stop welding but the machines was still on and the 55 volts were coming out of the negative and the positive terminals of the machine. The fan was still on and that means it was not an overheating problem.

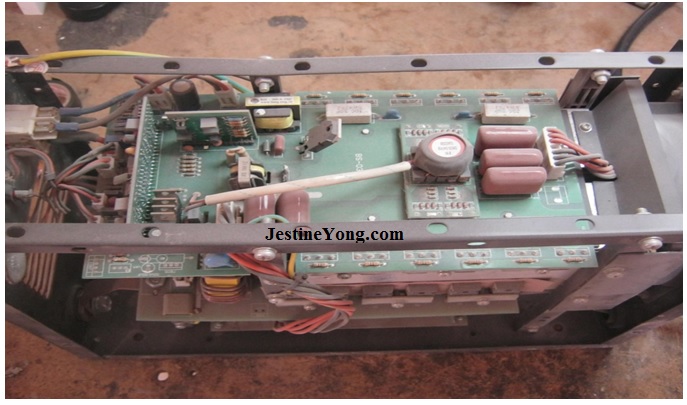

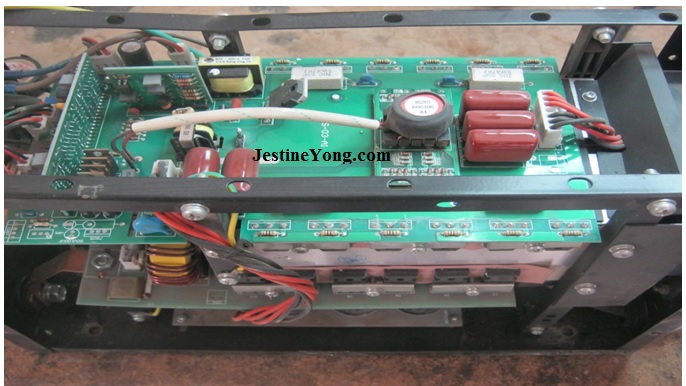

I took the cover off and looked inside. There was dust covering the surface of that board and it had to be cleaned.

It is always a good idea to blow the dust away. It helps me to see if there are cold or loose soldering joints or any broken traces.

Note the difference between the two photos? From experience, a problem like that usually is a result of cold joints or loose soldering around the parts. That was my main focus with this repair.

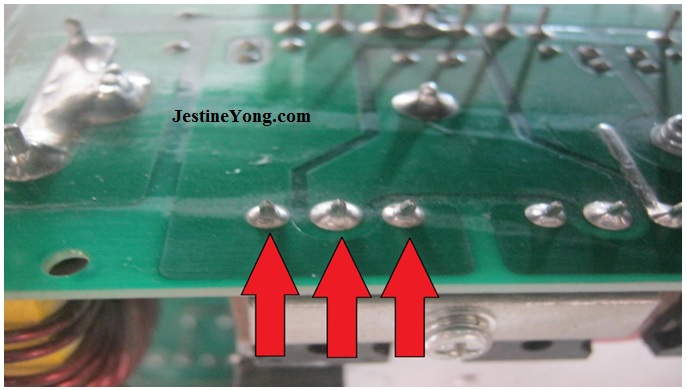

That was my first finding. The first joint on the left side of the photo is the worse one. So I had to re solder all the three pins.

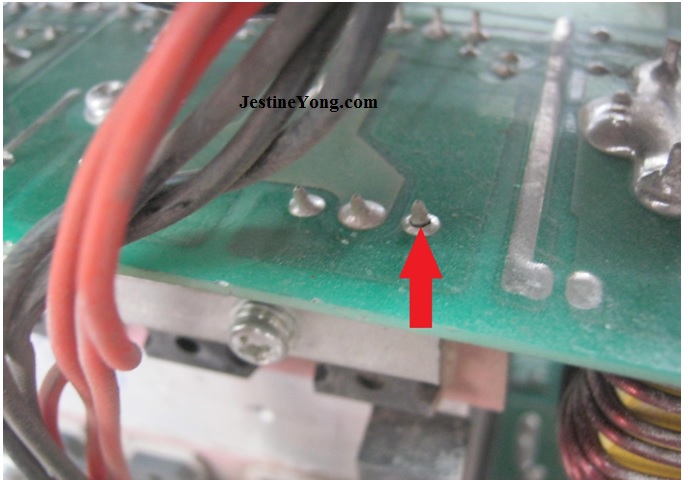

That is my second findings and that was the worst. I had to re solder that as well. I did a detailed check of all the soldering joints on this machines and it seems like these only two were the main problem.

Once I took the machine back together, again, I took it back to my brother and he did some welding on it. This time, it kept working like a charm. Another thing I noticed is the welding cables. Look how nasty there are.

I gave a strong recommendation to the welding technician to replace all these bad welding cables. He agreed. Mission Accomplished.

This article was prepared for you by Waleed Rishmawi, one of our ‘Master Authors’ and currently working in the Bethlehem area of Palestine repairing electrical and electronic equipment.

P.S- Do you know of any your friends who would benefit from this content that you are reading now? If so, forward this website to your friends or you can invite your friends to subscribe to my newsletter for free in this Link.

Note: You can check his previous repair articles in the link below:

https://www.electronicsrepairfaq.com/safety-locks-on-a-microwave-oven-replaced-model-lg

Well, well that’s good!

I like welding machines repairs and I think Waleed is doing a great job of it.Shukran for sharing your repair tips with us. There is always something new for us to learn. Shukran so much.

Good job, Waleed. “Worked like a charm”, is a saying that’s also used by Americans, but we all know that charms don’t work.

Mr. Rishmawi,

Thank You for your Articles, I have found them very useful and enjoy them. One additional comment I would like to make. I have seen on Welding and Plasma Cutter Machines, of this same design, The top support rails carry all the weight of the circuit boards and components. These rails are not rigid enough and bend down allowing some top circuit boards to crack, even break. The one in your pictures seem to be sagging a little, at the hanger joint. I have replaced these rails that are angle Shaped, with square tubing of the same cross section dimensions, and seems to eliminate the problem. I think this is due to from rough handling and in shipping. Thank You for your Time and Talents.

Another good repair Waleed. Since it was such an old device it makes me question if the new silver solder (without the lead) will be any better in the future concerning those bad joints.

Thank you sir Waleed for sharing us your repair experience in this machine i love reading all news letter from sir jestine and all those that shared by professionals like you sir.

good work sir